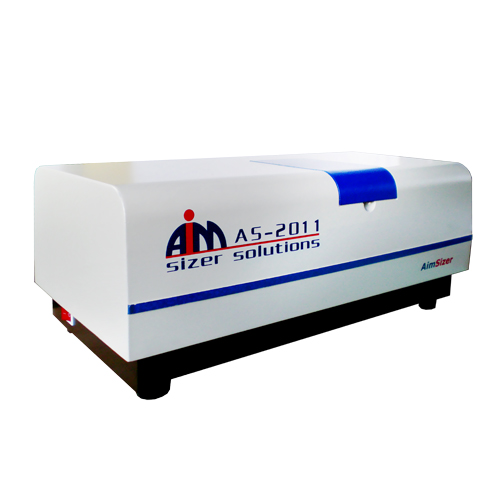

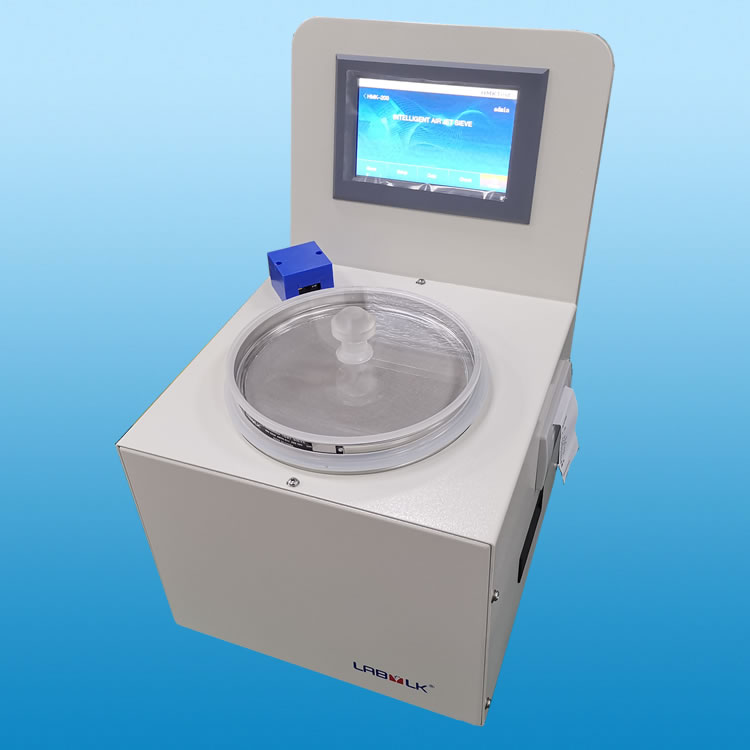

What products does AIMSIZER have related to particle size? The particle size-related products developed by AIMSIZER and widely used by users include: AS-2011 Laser Particle Size Analyzer, AIR-200 Standard Air Jet Sieving Machine, HMK-200 Intelligent ... Read more

The special particle size distribution analyzer for plastic materials PES-polyether sulfone is air jet sieve. Polyether sulfone resin (PES), a thermoplastic polymer with excellent comprehensive performance developed by ICI in 1972, is one of the few ... Read more

When purchase the Air Jet Sieve, you can purchase the cyclone sample collector at the same time. By using the latest technology, the particle under the sieve can be collected up to 99.9%. The Air Jet Sieve divides the particles into particles on the ... Read more

What is Particle Size Distribution D50, D50 Particle Size Distribution Particle Size Distribution D50 is also known as median diameter or medium value of particle size distribution, it is the value of the particle diameter at 50% in the cumulative d ... Read more

Mesh to Micrometer Conversion ASTM E11 Standard Specification for Wire Cloth and Sieves for Testing Purposes. ISO 3310-1 Test sieves – Technical requirements and testing Part 1: Test sieves of metal wire cloth ISO 565 Test sieves — Metal wire ... Read more

Hosokawa, Alpine Air Jet Sieve and Alpine Air Jet Sieve and e200LS_Hosokawa e200LS Air Jet Sieve are the same type air jet sieve produced by the same company. Hosokawa is a Japanese name. Alpine is the company established in German by Hosokawa. The i ... Read more

Significance of Tapped Density and Tapped Density Tester 301-51 335pic The Tapped Density and the Compacted Density The tapped density is significant. The most important is that through measuring the tapped density, the powder’s fluidity can be calculated. Second is that the tapped density can guide transporting powder ... + Read more

How To Measure Tapped Density. Tapped density is an increased bulk density attained after mechanically tapping a container containing the powder sample.Tapped density is obtained by mechanically tapping a graduated measuring cylinder or vessel containing a powder sample.After observing the initial powder volume or weig ... + Read more

The Chinese national standard for determination of bulk density of metallic powders is GB 1479. Calibration powder Chinese emery 515pic-336pic ... + Read more

EP 2.9.16-1 Pharmaceutical Flowability Test EP is European Pharmacopia,it’s 2.9.16 is about testing procedure of pharmaceutical flowability. HMKFLow 329 is to be used. POWDER ANGLE OF REPOSE HMKFlow 329 is an apparatus of angle of repose conforming to USP 1174 , HMKFlow 329 is used to measure the angle of repose of pha ... + Read more

Carney funnel carney funnel is a funnel made of copper in specific size according to international standards carney funnel has an orifice of diameter 5.0 mm carney funnel can be used in apparent density testing carney funnel can also be used in flow rate determination 303 Carney Funnel-336pic ... + Read more

Method II – Measurement in a Volumeter,Scott Volumeter This part is about USP 616 Method II. A scott volumeter is a popular device used to measure the bulk density of bulk powders. AS-200 Scott Volumeter AS-200 has been widely user in pharmaceutical applications. AIR-200 Air jet sieve is a laboratory air jet sieve th ... + Read more

Copyright © 1997-2025 AIMSIZER SCIENTIFIC PTE.LTD. Tel. 0065-31388988 sales@aimsizer.com, aimsizer@hotmail.com All Rights Reserved