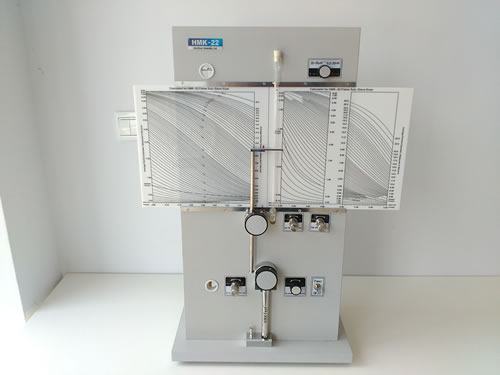

201-54 Study on the effect of process parameter control on the particle size distribution of molybdenum powder fisher sub sieve sizer

The average particle size and particle size distribution of molybdenum powder after reduction are evaluated by HMK-22 fisher sub sieve sizer and HMKTest laser particle size meter through changing MoO3 raw material particle size and primary and secondary reduction parameters. The results show that: there is no direct linear relationship between MoO3 raw material particle size and molybdenum powder particle size and particle size distribution after reduction. The wider the particle size distribution of raw material is, the smaller the average particle size of reduced molybdenum powder is. The material layer thickness of MoO3 is increased during primary reduction, the particle size of reduced molybdenum powder also increased, the particle size distribution becomes wider, and the D(0.5) value decreased slightly. The hydrogen dew point goes up, the particle size of reduced molybdenum powder increased, the particle size distribution becomes wider, D(0.5) value increased. The lower the secondary reduction temperature is, the smaller the particle size of molybdenum powder is. But the reduction temperature has little effect on the particle size distribution. With the increase of the thickness of the material layer and the decrease of the hydrogen flow, the particle size of the reduced molybdenum powder increased, and the particle size distribution curve shifted to the right.