Advantages And Disadvantages of Different Particle Sizing Methods

Advantages and Disadvantages Of Different Particle Sizing Methods

For user who wants to do particle size analysis of his specific powders, knowing advantages and disadvantages of particle size analysis method is significant to choice among instruments and finally successfully buy right instrument.

- Air Permeability Fisher Method

A fisher sub sieve sizer works on air permeability fisher method. Compared to other particle sizing method, it has advantage of

A:low cost of instrument, sample dispersion not an issue, testing on magnetic powders or hard alloy capable, directly read particle size.

D:only average particle size available, particle size distribution unobtainable

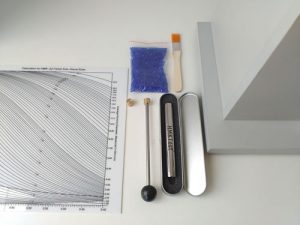

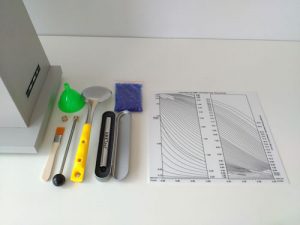

- 201pic

- Calculation Reading Chat

- Average particle size analysis

- 201pic

- Sieve Analysis

A:Advantages of the sieve analysis especially advanced air jet sieve analysis include fast and easy handling, low instrument cost, accurate and reproducible particle sizing results, short anlaysis time and the possibility to separate particle size grades or fractions by meshes. As a result air jet sieve method is a widely accepted alternative analysis methods using laser light or image processing method.

- 515pic

- 515pic

- airjetsieve200lsn

- HMK-200 Air Jet Sieve

- Laser Diffraction

A:easy operation, broad test range, high degree of accuracy and repeatability on-line test and dry test available.

D:test results are subject to distribution pattern, high cost of instrument

- Microscope Imaging

A: simple, direct test procedure, shape analysis available

D: long test cycle, relatively poor representation, testing of ultra fine particles not possible

HMK-CD7 Image Shape Analysis System

- Sedimentation

A:low price, continuous operation, high degree of accuracy and repeatability, relatively broad test range

D:long test cycle

BI-XDC Particle Size Analyzer X-ray Disc Centrifuge

- Coulter

A:easy operation short testing cycle, relatively high accuracy

D:narrower size range, easily blocked apertures, electric conductivity of medium necessary

Coulter Particle Counter

- Electron Microscope

A:capable of measuring particles of nanometer size, high resolution

D:possible alternation of particles during sample preparation, small representation of overall sample, and high cost

- Ultrasonic

A:direct test on highly concentrated liquid

D:low resolution