- PRODUCT DETAIL

- WHO BUY

- WHY BUY

- KNOW MORE

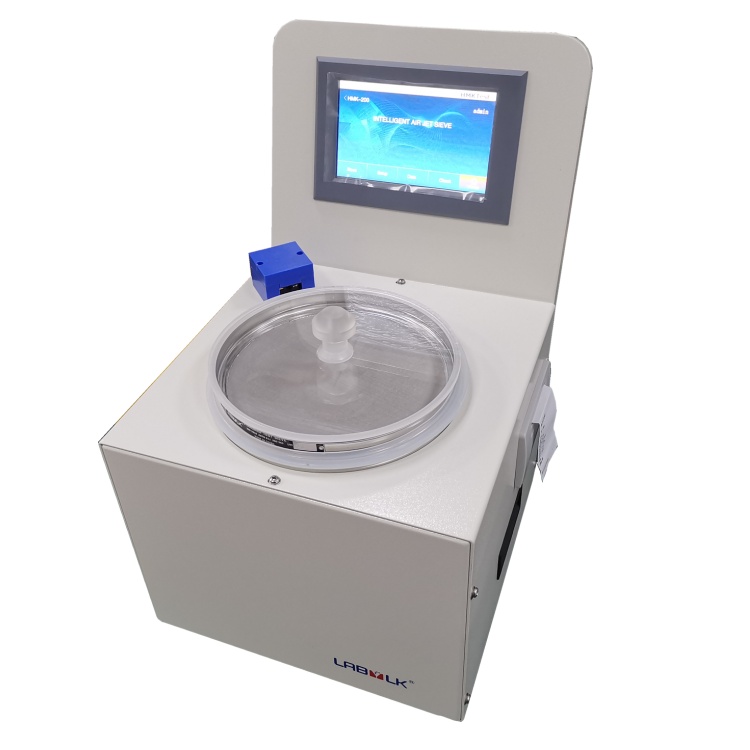

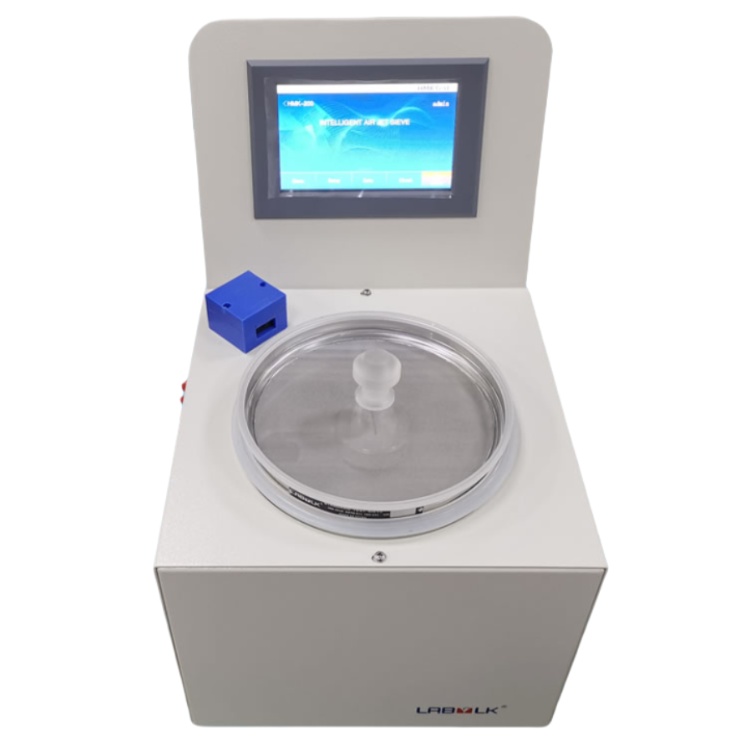

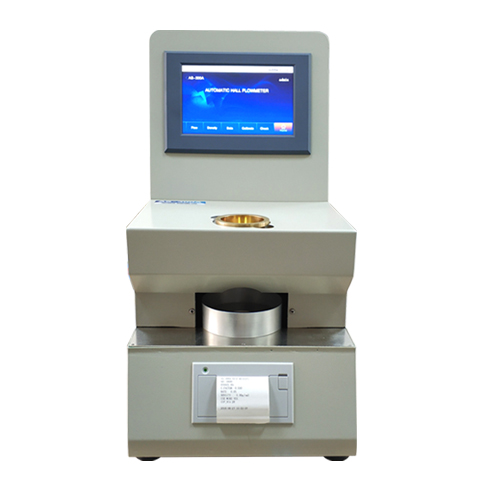

AIR JET SIEVE

AIR-200 Standard Air Jet Sieve meets higher requirement on air jet sieving method. Login on system with Admin password, put test sieve on the instrument, set No. of test, time of test, pressure of test and weigh sample and input data either manually or via optional RS-232 balance.Touch timer to start instrument and vacuum automatically, adjust the pressure if required. When stop re-weigh remaining sample and input data as beginning.The operating system analyzes and calculates the results automatically and output on an internal printer.

SPECIFICATIONS

- Size range: 15-5000 micrometer

- Accuracy: <1%

- Repeatability error: <1%

- Sieving time: 0-9999 min 99s

- Negative pressue: 0–10 KPa

- Motor speed: 18 rpm

- Log method: pass word

- Data input: manually or by optional balance

- Data calculation: Auto

- Result output: printer

- Operating system version: FS-AO(filtering/sieving/analysis/output)

- Size: L35 x D35 x H58 cm/11.8 Kgs/110-220V/50-60Hz/10A/70W

WORKING PRINCIPLE

Advanced electronic turbine generator and negative force work together to give powerful negative air jet that drives the particles from the nozzle then upwards until collision with the top sieve cover. De-agglomerated particles is re-vacuumed back towards the sieve cloth. Smaller particles pass and accumulate in vacuum or sample collector, bigger particles stays on sieve cloth. A satisfying sieving process is thus accomplished. Size limit with one sieve or particle size distribution with multiple sieves.

APPLICATIONS

- Microcrystalline cellulose

- Lactose

- Cellulose Ether

- Coating powders

- Plastics

- Epoxy powder

- Powdered activated carbon

- Dry powders particle sizing, Ceramics,Chemical products,Cinnamon,Cork,Cosmetics,Dental ceramics,Face powder,Flour,Food,Gypsum,Limestone,Minerals,Pharmaceutical materials,Pigments,Plastics,owder coating,Rubber,Sandstone,Soy flour, Sugar, Tea,Toner,Washing powder,General industrial etc.

- Especially for those powders hard to sieve or can be sieved but with bad sieve results due to small density, agglomeration, floating, mesh aperture blocking or electro-static

WHO BUY

Argentina

- Laboratorios Agentinos

Brazil

- Unimetal Ind. Com. e Emp. LTDA.

Canada

- Graymont

Columbia

- Cementos

Egypt

- Egycoat paints(Colorama) LTD.

India

- NOVA INSTRUMENTS PVT.LTD.

- Gimpex

- Lucas Technologies

Lebanon

- RITVER SAL

Malaysia

Mexico

- Micro de Mexico

Pakistan

- Bestway Cement

- MN ENTERPRISE

South Korea

- Solvit Medical

Spain

- B&B TRENDS, S.L.

Sweden

- Nanexa AB

Taiwan

- Fatin Enterprise Co., Ltd.

UK

- Staffs Powder

- Whitford Ltd.

USA

- Stewart Superabsorbents LLC

- Ionic Materials

- MM Development

- Watson Inc.

- ILNP Cosmetics

- Worcester Polytech Inc.

- WPI

- MolyWorks Materials Corporation.

WHY BUY

STANDARDS:This instrument is designed in accordance with international standards, such as ISO, ASTM, USP, EP

- ISO 4610 Plastics -- Vinyl chloride homopolymer and copolymer resins -- Sieve analysis using air-jet sieve apparatus

- ASTM D5158 Standard Test Method for Determination of Particle Size of Powdered Activated Carbon by Air Jet Sieving

QUALITY: This instrument uses robust materials and durable components, including CE and UL certified parts

- CE

- UL

EXPERIENCES: This instrument has been used and validated by a large number of industry customers worldwide

- up to 500 users around the world

SHIPPING: All shipments are made by global express such as DHL, FEDEX, UPS, AIR CARGO

- DHL

- FEDEX

- UPS

- AIR CARGO

SERVICE: All operations are accompanied by detailed descriptions, pictures and videos

- Free warranty 2 years

- Descriptions

- Pictures

- Videos

MAINTENANCE: All repairs are simple, replacement components are available for a long time

- Work without consumable parts

- Easy to replace modules