- PRODUCT DETAIL

- SPECIFICATIONS

- FEATURES

- APPLICATIONS

- PRINCIPLE

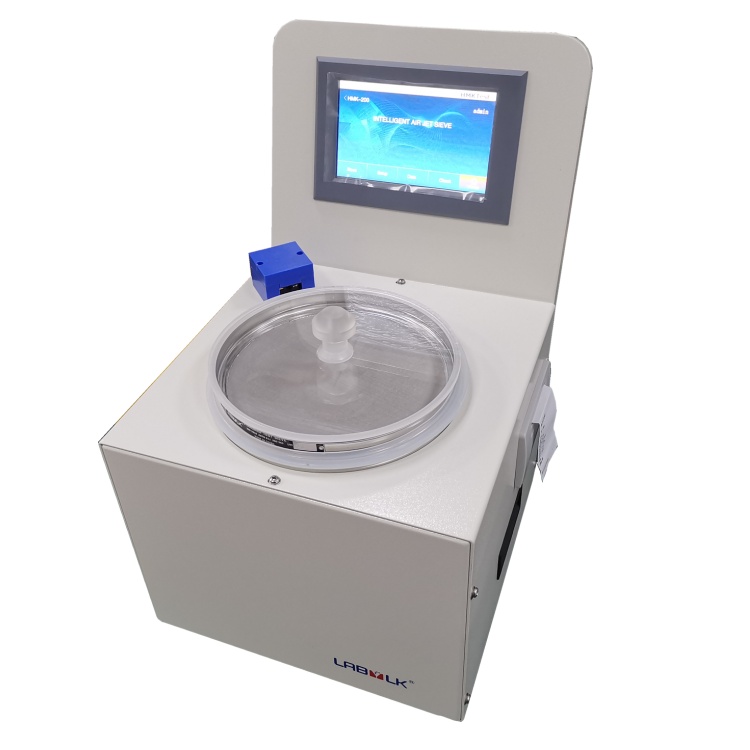

HMK19 Vibrating Screening Machine | Vibrating Sifter | Vibration Sieve

HMK19 Vibrating screen/Vibration screen is a type of functional screening machine/sieving machine for industrial use.

It is widely used in various industries, not only in fine sieving, but also in screening medium size or crude powders.

If you are looking for a lab sieve for particle separation or particle size distribution analysis, kindly view our

SPECIFICATIONS

FEATURES

- HMK19 Vibrating screen features small size, light weight, easy to move

- The direction of the discharge port can be flexibly adjusted, both coarse and fine powders can be automatically excluded,

- High precision, high efficiency, applicable to any powders, granules, mucus etc.

- Mesh cloth is not subject to block, the powder is not subject to flying, up to 500mesh (28 micrometer)

- Unique grid design, robust screen cloth and easy and fast replacement as fast as 3 to 5 minutes, easy to operate, easy to clean

- No mechanical movement, easy maintenance, single or multiple tier are available as per user’s requirement.

- Easily upgrade to HMK-GF2 Ultrasonic Vibrating Screen.

APPLICATIONS

- Food industry

- Flour, milk powder, powdered sugar, salt, milk, egg powder, starch, spices, dextrin, fruit juices, beverages, rice, soy sauce, yeast mixture, pineapple juice, fish meal and so on.

- Chemical industry

- Resin powder, paint, industrial chemicals, cosmetics, paint, powder, PVC resin powder, citric acid, polyethylene powder, washing powder and so on.

- Metal, Mining and Metallurgy

- nbsp;Aluminum powder, lead powder, copper powder, ore alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electric magnetic materials, abrasive powder, refractory materials, kaolin, lime, alumina, heavycalcium carbonate, quartz sand, etc.;

- Pharmaceutical industry

- Chinese herb powder, liquid, medicine liquid, pharmaceutical intermediates etc.

- Abrasive ceramics metallurgical industry

- nbsp;Quartz sand, alumina, mud, kaolin, synthetic black aluminum, spray soil particles, silicon carbide, iron, silicon carbide, lead powder, titanium dioxide and so on.

- Nuisance processing

- nbsp;Waste oil, waste water, dyeing and finishing wastewater, additives, activated carbon, etc..

PRINCIPLE

- The powder moves at certain angle with the screen cloth on the vibrating screen/vibration screen.

- Such move helps the powders on the screening machine mesh cloth divide into multiple layers.

- At the same time it prevents the mesh cloth being blocked by the particles.

- The particles violently vibrate at small amplitude(normally 0.5-5mm) but at high frequency(600-3000/min) instead.

- Such design prevents mesh from being blocked and optimizes the screening efficiency.

- HMK19 consumes small power with simple structure and easy maintenance.

- They are used in separatiing operations such as dehydration and desliming.

- HMK19 is a new type of screening machine using vertical motor as excitation source.

- 2 eccentric weights are mounted on both top and bottom of the motor.

- Such design divide the rotary motion of the motor into 3 dimensional motion i.e. level motion, vertical motion and inclined motion.

- 3 motions are then passed to the mesh cloth. Phase angle on top and bottom are adjustable in order to change the material motion on the screen cloth.

- HMK19 is also known as a vibro energy separator.